A probe integrity inspection is used to identify leaks too small to be detected during the probe block step of the self-check. It involves connecting an ignited phx42 to a supply of zero air and running an alcohol-based wipe along the whole length of the probe, while watching the handheld for deflection.

The best practice is to conduct a probe integrity inspection every week and/or anytime you have a drift or calibration failure, or suspect a probe problem. See the Level 1 Probe Integrity Inspection procedure for more information on the inspection process.

Note: A probe integrity inspection is NOT…

- A visual inspection

- Blocking the probe tip

- Swapping a suspected leaking probe with a “known” good probe

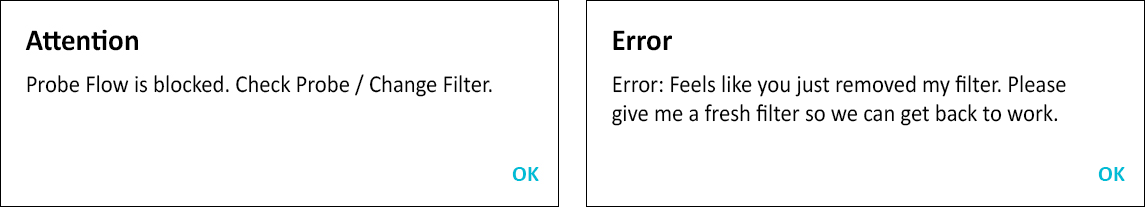

In the event a filter error is not resolved when following the on-screen prompts during a self-check, a probe testing adapter (LDAR#4300) should be used. The probe testing adapter is designed to help identify the root cause of filter-related errors (see error samples below).

For details on properly using the probe testing adapter, see the Probe Testing Adapter procedure.