Note: Click here for a print copy of the H2 fill adapter maintenance and installation procedure.

Fill Adapter maintenance is critical for successful operation of your phx42.

- Remove the H2 quick-fill cover (LDAR#42908).

- Ensure the following:

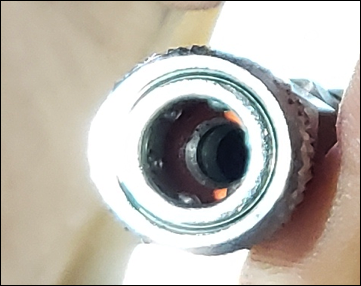

- Verify no dust or debris is in the H2 Fill Port.

- Verify no dust or debris is in the H2 Fill Adapter.

- Verify the arrow on the red handle is pointing to the breather side of the fill valve.

- Verify the gauge nearest the cylinder reads ≤ 1800 psi. If not, adjust the regulator.

- Note: Do NOT exceed 1800 psi or the pressure relief valve will vent.

- Note: Do NOT exceed 1800 psi or the pressure relief valve will vent.

- If pressure has bled off the H2 Fill Adapter, turn the red handle 180° for 2 seconds to bleed any air from the system before connecting to the phx42.

- Verify no dust or debris is in the H2 Fill Port.

- Power on the phx42.

- Connect the H2 Fill Adapter to the H2 fill port, then verify the connection by slightly pulling on the 3-way valve and spinning the collar.

- Turn the red handle 180° to open valve. The arrow should point toward the fill hose.

- Wait until the needle on the gauge stops moving.

- Turn the handle back 180° to close the valve. There will be a slight hiss from the release of pressure.

- Pull on the collar of the H2 Fill Adapter to release it.

- Twist the H2 quick fill cover onto the H2 fill port.

- Close the bottle. There is no need to bleed pressure off the H2 Fill Adapter.

Reminder: The phx42 MUST have the H2 quick-fill cover in place at all times unless filling.

A very small amount (as little as possible) of O-ring grease should be applied to the phx42 side of the quick connect once a month.

Your phx42 is now filled with H2, and while it has been designed to minimize possible leaks, you should handle and store it with caution.

Note: The pressure sensor on the phx42 will max out at about 1200 psi. The unit can actually hold up to 1800 psi. Use the regulator on your fill adapter to confirm you have filled to 1800 psi.

Tech Tips:

- Fill your cylinder at end-of-day to accomplish the following:

- The analyzer will have enough H2 for end-of-day drift.

- Being full overnight allows the calibrating tech to see if the pressure is stable or dropping (leak test).

- The analyzer will have enough H2 for end-of-day drift.

- Many successful uses have adopted a 2-fill practice: Mid-day and End-of-day.

- If the H2 Quick Fill Cover pops off, it’s likely there’s a H2 leak. Report an issue to Support and send the log files.

- For the best results, avoid operating the phx42 with an H2 supply of less than 400 psi. That much pressure is required to optimize the phx42’s ability to stabilize its lower H2 pressure. The phx42 WILL NOT operate with an H2 supply of less than 300 psi.

- If the H2 Quick Fill Cover is missing, replace it.

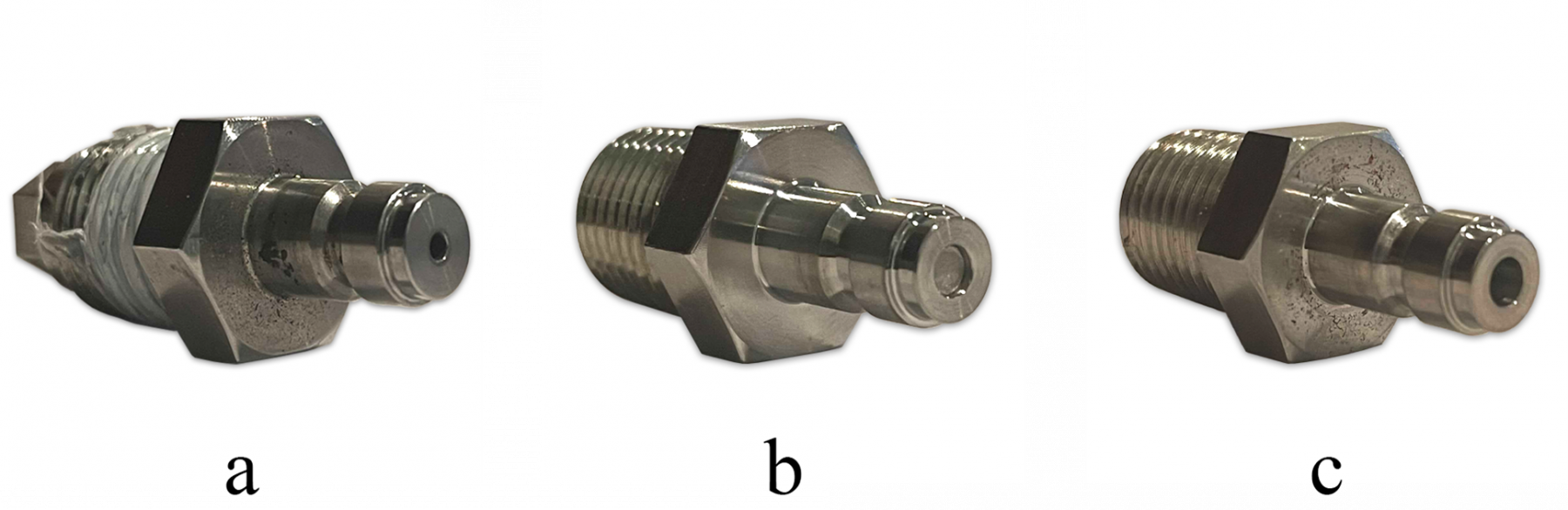

- If using the v2 H2 Fill Port and the filter is missing (figure c below), report an issue immediately.

| Figure a | v1 H2 Fill Port |

| Figure b | v2 H2 Fill Port with the filter in place |

| Figure c | v2 H2 Fill Port missing the filter |